Industrial

Hankook brings latest technologies together through continuous research

and development to maximize our battery performance.

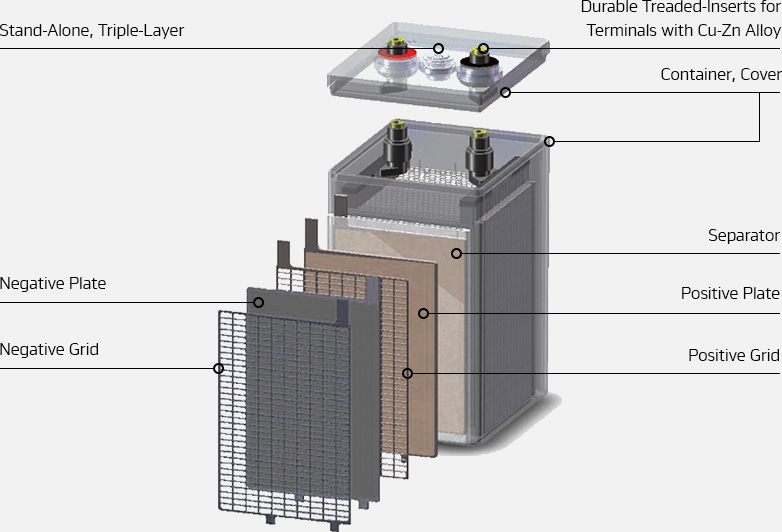

2V AGM Technology

First Use of Stamped Grid in Korea

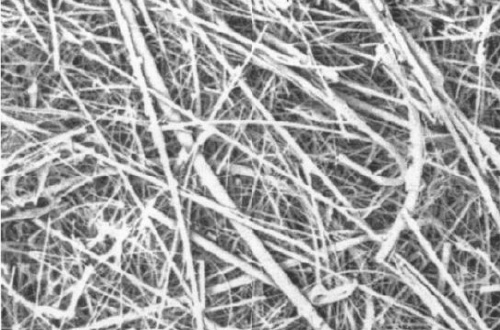

Longer battery life with cold-rolled stamped grid and special tissue material

- Improved corrosion resistance

- Suppresses the Grid growth

- Prevents loss of active mass

Application of VRLA

(Valve Regulated Lead Acid) Technology

Maintenance-Free Structure with AGM Technology

- Best AGM design technology provides excellent reabsorption of gas into electrolyte.

- 100%-Inspected stand-alone bent caps increases the uniformity between the products in the cell.

- Triple-layered design structure for blocking leakage increases stability of the battery.

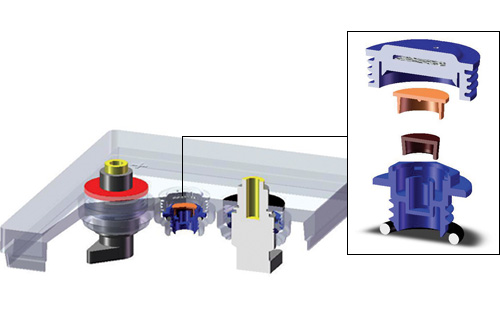

Durable Treaded-Inserts for Terminals

Maximization of High-Rate Discharge Effect

- Highly-pure special copper alloy

- Minimization of internal resistance

- Excellent vibration resistance (cable clamping)

Application of Special AGM Separator

Reduces the effects of electrolyte stratification

- AGM separator with greater surface area

- Thickness of glass-fiber in the combination of fine & coarse fibers